Fixed-Speed Screw Compressors

Constant Airflow and Pressure

nothing here

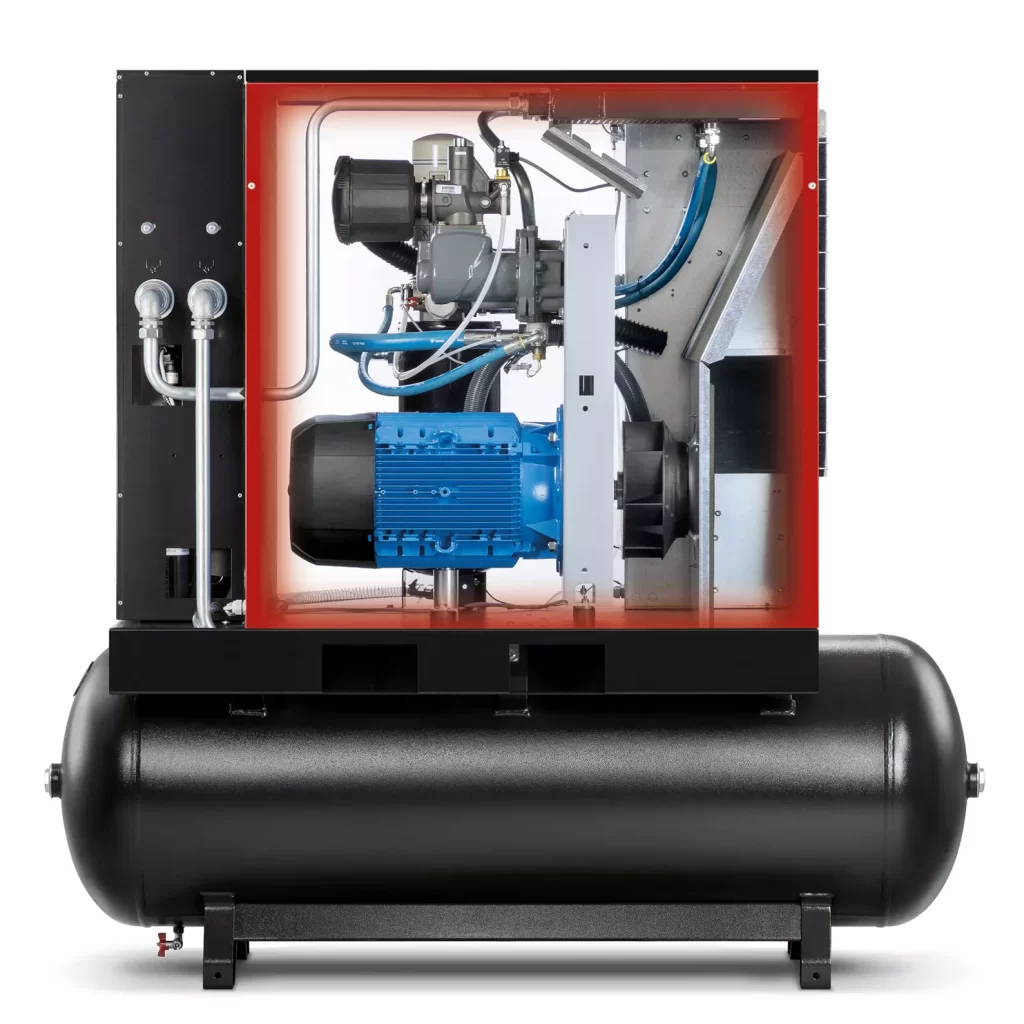

AIRPLUS installs CP fixed-speed screw compressors to produce a constant airflow, matching compressor speeds to pressure demands. Geared or belt-driven models are available.

Chicago Pneumatic Fixed-Speed Screw Compressors

AIRPLUS offers Chicago Pneumatic fixed-speed screw compressors which are preferred when a constant airflow is required. Gear or belt-driven models are available.

Advantages

Simplicity

Fixed-speed screw compressors are simpler in design and operation than variable-speed screw compressors, making them a preferred choice in applications where a constant flow of compressed air is required. Since they operate at a fixed speed, there are no additional controls or systems needed to regulate the speed, which reduces the complexity of the compressor system.

Cost-Effective

Fixed-speed screw compressors are generally less expensive than variable-speed screw compressors, making them a cost-effective solution for applications where the demand for compressed air is consistent and predictable. Since they do not require sophisticated controls or monitoring systems, they are also less expensive to maintain over the long term.

High Loads

Fixed-speed screw compressors are capable of operating at full load for extended periods of time, making them a preferred choice in applications where the compressed air demand is high and constant. Since they operate at a fixed speed, they can handle high load factors without the need for frequent adjustments or downtime, which can improve productivity and efficiency in the manufacturing process.

Fixed vs. Variable Speed Screw Compressors

When it comes to selecting a compressor for industrial applications, there are many factors to consider, including efficiency, reliability, and cost-effectiveness. Two common types of compressors installed in industrial settings are fixed-speed screw compressors and variable-speed screw compressors. While both types have their advantages and disadvantages, there are certain scenarios where one may be more suitable than the other.

Fixed Speed

Fixed-speed screw compressors are the simpler and more cost-effective option, making them a popular choice for applications where a constant airflow is required. They operate at a constant speed, delivering a steady flow of compressed air at a consistent pressure. Fixed-speed screw compressors are best suited for applications where the demand for compressed air is relatively constant and predictable, such as in a manufacturing plant where production runs are consistent.

Variable Speed

Variable-speed screw compressors are more energy-efficient and offer greater flexibility in meeting changing demands for compressed air. They operate at a range of speeds, automatically adjusting their output to match the required demand for compressed air. Variable-speed screw compressors are ideal for applications where demand for compressed air fluctuates, such as in a facility with varying production levels or processes that require intermittent bursts of compressed air.

Conclusion

The choice between a fixed and variable-speed screw compressor will ultimately depend on the specific needs and demands of the application. Careful consideration of factors such as energy efficiency, initial cost, and demand variability will help to determine which type of compressor is the best fit for your facility.

Fixed-Speed Screw Compressor Models

CPN 3-20HP

Our CPN 3-20HP compact rotary screw compressor range is ideal for small industries with applications such as winery, garages, paint shops, tire shops, etc. The CPN is the smallest stationary screw compressor in the range, combining the simplicity and cost effectiveness of a piston with the durability, technology and energy efficiency of a screw compressor.

CPM 3-20HP

Easy to use, efficient and reliable, our CPM rotary screw compressors are ideal for service or light industrial applications. Specially designed for high performance, they effortlessly meet the compressed air demands of tire shops, paint shops, car dealers or maintenance shops. CPM is a complete solution in a compact package.

CPF 180 - 420

Gearbox-driven oil-injected screw compressors

Our new CPF 180-420 is developed for harsh conditions and ambient temperatures up to 46°C. it is characterized by In-house designed and produced new screw elements; gear driven transmission; IE3 premium efficiency motor and much more.

CPC 40-60 G

Experience the innovation and worry-free operation of the upgraded Chicago Pneumatic gear drive series of rotary screw air compressors. The range stands out in the market for its reliability, simplicity and energy efficiency. The new compact design offers a 25% smaller footprint compared to the previous generation.

CPC G 40-60 / CPD G 75-100 / CPE 100-150

The Chicago Pneumatic CPC G / CPD G / CPE range consists of highly qualified gear driven oil-injected screw compressors. They are compact, solid, easy to install and need very low maintenance. The range is now available from 40 to 150 hp, with or without dryer, with fixed speed control. Whatever model you choose it will provide your workplace with high class compressed air equipment.

CPA 7.5-20HP & CPB 25-40HP

The CPA-CPB Series more than a decade ago. These compressors quickly gained a reputation for their top quality and performance to match. Over the years, their design evolved in order to better adapt to new customer needs: all-in-one, powerful and silent screw compressors. Their user-friendliness and reliability make the CPA and CPB the screw compressors to beat for tough working conditions.

CPC 40-60

Our CPC belt driven oil-injected rotary screw compressors provide a compact and easy to install source of compressed air. Available from 40 to 60 hp, with or without dryer, with fixed speed control. Enjoy strong reliable performance alongside high energy efficiency.

QRS 3-20

Our QRS is the leading rotary screw compressor for service or light industrial applications. Specially designed for high performance, efficiency and reliability our QRS rotary screw compressor range will meet the compressed air demands of a tire shop, maintenance shop or paint shop.

CPC/D 40-75

Our CPC/D belt-driven oil-injected rotary screw compressors provide a compact and easy to install source of compressed air. Available from 40 to 75 hp, with fixed speed control. Enjoy strong reliable performance alongside high energy efficiency.

CPD 75-100 G

The CPD-G range consists of highly qualified gear driven oil-injected screw compressors. They are compact, solid, easy to install and need very low maintenance. The range is now available from 75-100 hp, with or without dryer, with fixed speed control. Whatever model you choose it will provide your workplace with high class compressed air equipment.

CPM 21-40

Easy to use, efficient and reliable, the CPM Series meets the compressed air demands of tire shops, paint shops, car dealers, maintenance shops, etc. Easy to use and quiet by design, the CPM can be installed almost anywhere in the workshop, without disturbing your working environment. Base mounted or tank mounted, with or without a dryer, the CPM is a complete solution for your business.

CPBg 20-35

Chicago Pneumatic sets a new standard in high efficiency, low noise level, and outstanding reliability with the new CPBg 20 – 34 range. These units come with a new element, a high-performance gearbox, and premium efficiency motors. The wide range of options allows you to easily customize your CPBg, while its unique design satisfies your needs in terms of user-friendliness, reliability and lifetime duration. All in all, it is the ideal screw compressor for high energy efficiency and hard working conditions.

CPCM 40-60

A highly reliable gear transmission

A belt-driven compressor has a higher risk of downtime and maintenance- related costs. Unscheduled belt tensioning and replacement cause productivity losses and there is always the risk of post-service belt misalignment. That is why the CPCM comes with a gear drive transmission. You have no belts to replace and enjoy lower operating (service) costs. What is more, the CPCM is 3% more energy efficient compared to belt-driven compressors.

CPM TMDD series

CPM TMDD 4kW – 18.5kW oil-injected screw compressors series is built on a trustworthy technology which increases its efficiency and makes CPM TMDD screw compressor a reliable performer. These ranges are also suitable for more demanding applications and can be deployed in harsh working conditions.

Contact Us - We Can Help

Choosing the right compressor for your application is dependent upon many factors. AIRPLUS Industrial has 30+ years of experience in designing, sourcing, installing and maintaining these systems — we can help you choose the right system for your facility.