DV Systems Heavy-Duty Piston Compressors

Heavy-Duty Industrial Reciprocating Compressors

nothing here

AIRPLUS Industrial installs DV Systems HD piston compressors where compressed air requirements are demanding & reliability for long duty-cycles is paramount

DV Systems design, engineer and manufacture reliable industrial air compressors for demanding environments and provide comprehensive compressed air solutions for your application’s compressed air needs. Made in Barrie, ON, Canada

Features & Benefits

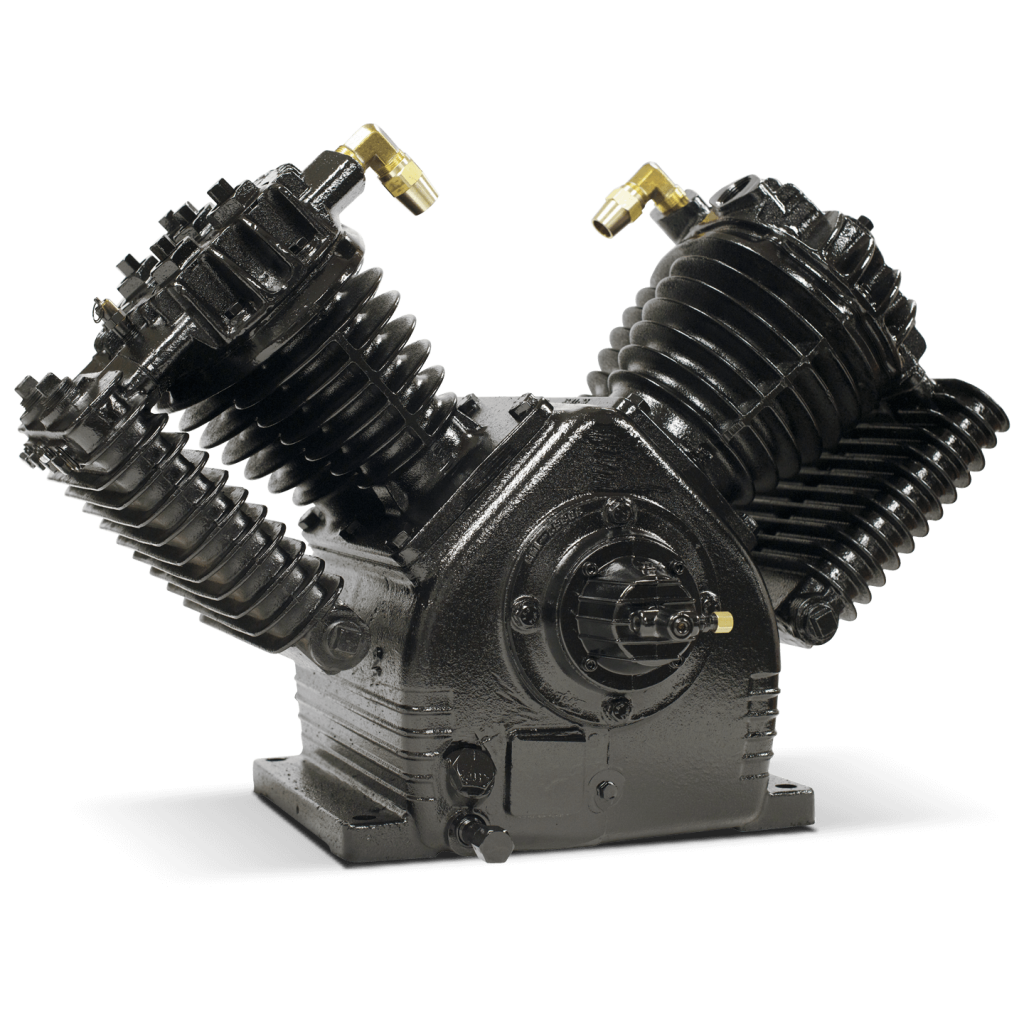

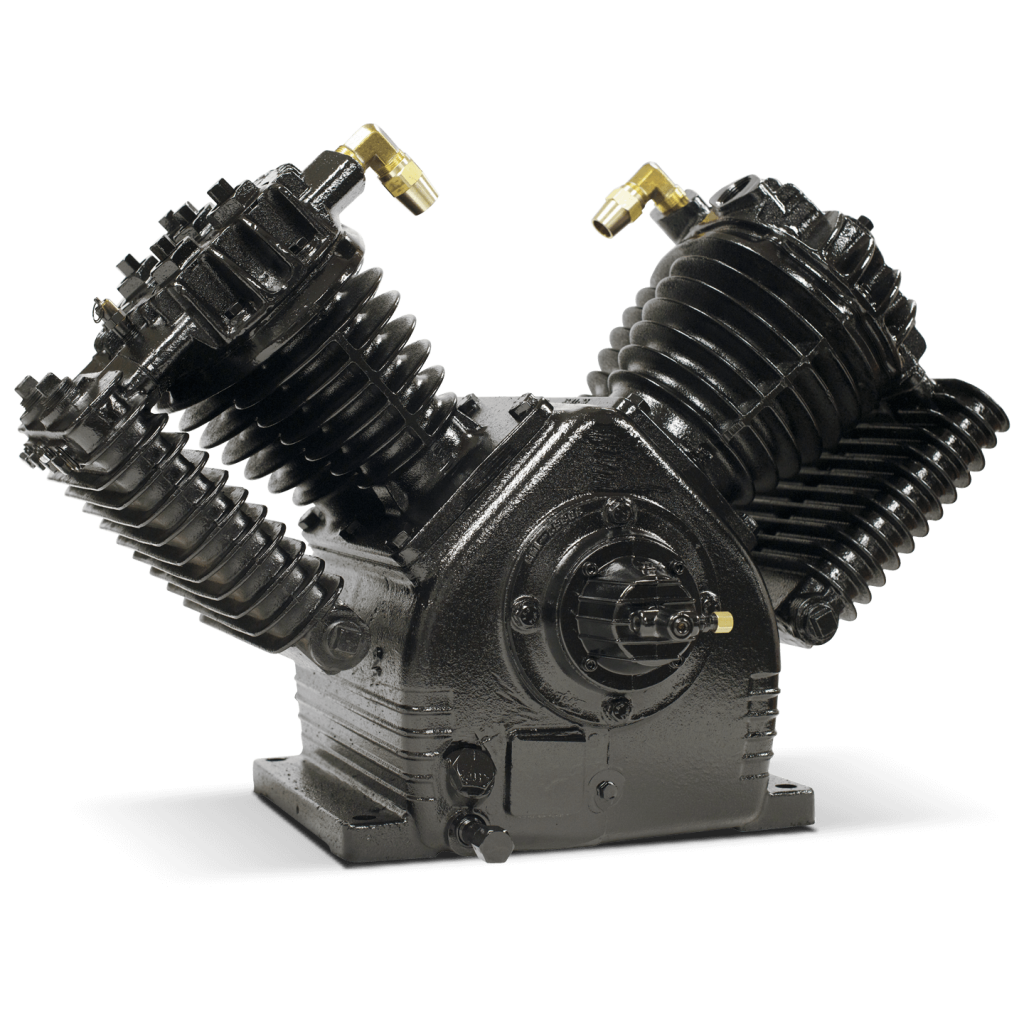

DV Systems Heavy-Duty Industrial Reciprocating Compressors are heavily-weighted, 100% cast-iron, pressure-lubricated compressor pumps with slow rpm that enhance heat dissipation and feature an 80% duty cycle. Reciprocating air compressors from DV Systems are built for demanding industrial applications. They are available in a wide range of horsepower ratings, including models that are gas driven for mobility.

✔ Smooth, Free-Running Operation

Balanced crankshafts and precision ground journals, combined with heavy-duty ball-type main bearings, provide smooth, free-running operation.

✔ Precision-Machined Cylinders

All cylinders are precision honed and machined to exact tolerances, reducing wear and friction.

✔ Smooth, Vibration-Free Operation

Dynamically balanced, Airfoil-Type Flywheels provide a continuous flow of cooling air over all parts of the compressor.

✔ Controlled Lubrication

DV’s proprietary pressure lubrication process provides controlled lubrication to all critical areas by means of oil ring pickup

✔ Cool, Maintenance-Free Operation

Short stroke load matched pistons, combined with high quality alloy steel disc-type valves permit cool operation and maintenance-free service.

✔ Short Stroke Design

Large bore, short-stroke and slow operating speeds improves life expectancy and provides high air delivery.

DV Systems Heavy-Duty Reciprocating Compressor Models

Heavy Duty Industrial Series

The pressure-lubricated heavy duty industrial series is engineered to provide a durable and dependable air compressor built to withstand the most demanding industrial environments.

The moving components of these pumps are machined, honed, balanced and assembled in Canada. Rugged construction and long life allows DV to confidently offer an unprecedented 7 year warranty.

247 / 447 Compressor Pumps

✔ Smooth, Free-Running Operation

✔ Precision-Machined Cylinders

✔ Smooth, Vibration-Free Operation

✔ Controlled Lubrication

✔ Cool, Maintenance-Free Operation

✔ Short Stroke Design

2 Stroke

2 or 4 Cylendars

Additional Features & Benefits

✓ Solid, Cast-Iron Cylinders

Minimizes Distortion from Assembly Torque & Heat.

Precision-Machined Cylinder Walls Honed to reduce Friction & minimize Oil Carry-Over & Friction.

Extra deep fins provide increased cooling & strength.

✓ Balanced Pistons

Heat-Treated & Stress-Relieved Connecting Rods Cast from Ductile Iron & Assembled with Babbit Bearings Increase Durability & Reduce Wear on the Crankshaft.

High-Pressure, Cast-Iron Pistons withstand extreme forces. Low-Pressure Pistons made from aluminum alloy.

Extra wide compression rings designed to work seamlessly with the oil control rings & scraper.

✓ Balanced Crankshaft

Ensures smooth, extended-life operation.

Precision-ground journals furnished with inserts for long, trouble-free operation.

Tapered shaft for reliable & effective transmission.

✓ Balanced Flywheel

Airfoil-type spokes provide continuous, cooling air flow.

Smooth, Vibrationless Operation.

✓ Quiet, Quick Acting Valves

Machined, carbon-steel valves balance air passages & structural integrity.

Hardened carbon steel valve guides & stainless steel disc valves and springs

Individually tested & easily serviced.

✓ Cool Cylinder Head

Quick Cooling, Deep, Directional Fins.

Fast, efficient flow of cooler intake air due to compact, streamlined air passages in the cylinder head.

✓ Load Free Starting

10 HP & 15 HP Equipped with centrifugal pressure release (CPR) allowing the motor to start before a pressure load is applied to the pump.

✓ Air Receivers

CRN & ASME Approved.

Maximum working pressure: 200 PSI

Complete with pressure gauge & CRN & ASME Approved safety valve.

✓ Manifold Assembly

Two Pressure Switches Factory Pre-Set to Operate at 115/150 PSI (792.9/1034.kPa) Cut-In/Cut-Out

Maximum Operating Pressure Adjustable to 175 PSI (1206.6 kPa)

✓ Ball Bearings

Oversized, Heavy load capacity ball bearings ensures a free-running crankshaft.

Lubricated from the crankcase, requiring no maintenance.

✓ Deep-Finned Cast-Iron Intercooler

Enhances heat dissipation between compression stages.

25 HP Heavy Duty Industrial Series

✔ Smooth, Free-Running Operation

✔ Precision-Machined Cylinders

✔ Smooth, Vibration-Free Operation

✔ Controlled Lubrication

✔ Cool, Maintenance-Free Operation

✔ Short Stroke Design

25 HP

86.6 SCFM

145 PSI

15 HP Heavy Duty Industrial Series

✔ Smooth, Free-Running Operation

✔ Precision-Machined Cylinders

✔ Smooth, Vibration-Free Operation

✔ Controlled Lubrication

✔ Cool, Maintenance-Free Operation

✔ Short Stroke Design

15 HP

51.8 SCFM

150 PSI

13 HP - Gas Heavy Duty Industrial Series

✔ Smooth, Free-Running Operation

✔ Precision-Machined Cylinders

✔ Smooth, Vibration-Free Operation

✔ Controlled Lubrication

✔ Cool, Maintenance-Free Operation

✔ Short Stroke Design

13 HP

25.9 SCFM

150 PSI

30 HP Heavy Duty Industrial Series

✔ Smooth, Free-Running Operation

✔ Precision-Machined Cylinders

✔ Smooth, Vibration-Free Operation

✔ Controlled Lubrication

✔ Cool, Maintenance-Free Operation

✔ Short Stroke Design

30 HP

99.9 SCFM

150 PSI

Contact Us - We Can Help

Choosing the proper system for your application is dependent upon many factors. AIRPLUS Industrial has 30+ years of experience in designing, sourcing, installing and maintaining these systems — we can help you choose the right system for your facility.